Lubrication with crimping nipples

Your grease nipples crimped with ease

Hydrokit offers you a revolutionary solution in the world of lubrication.

Indeed, it is the solution to accompany you on your building sites during the assembly of the lubrication hoses.

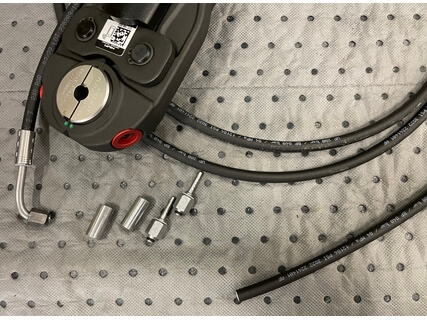

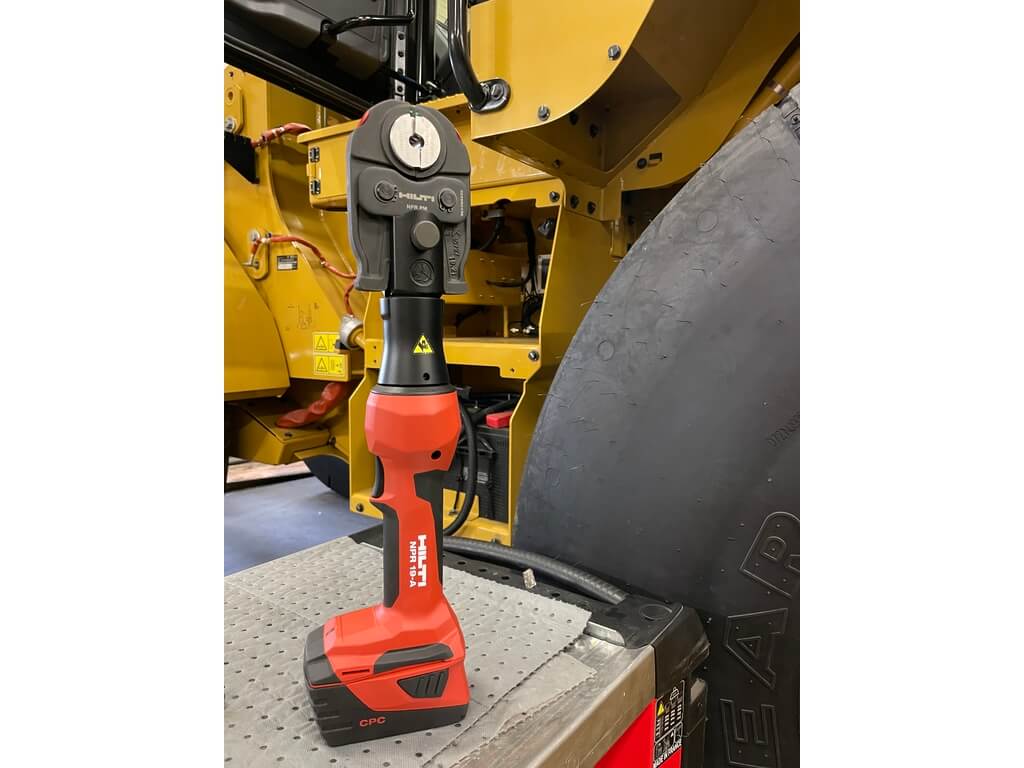

The use of specific end caps and a cordless crimping machine allows you to crimp and assemble the hose directly on the machine.

This only takes a few seconds and saves valuable time when installing a lubrication system.

Why crimping nipples for lubrication?

1 - COMFORT

Reduction of RSI * compared to the use of retrievable tips.

2 - PERFORMANCE

Time saving on your assemblies. The crimper saves you 50% of time on the installation of your fittings.

3 - PRACTICAL

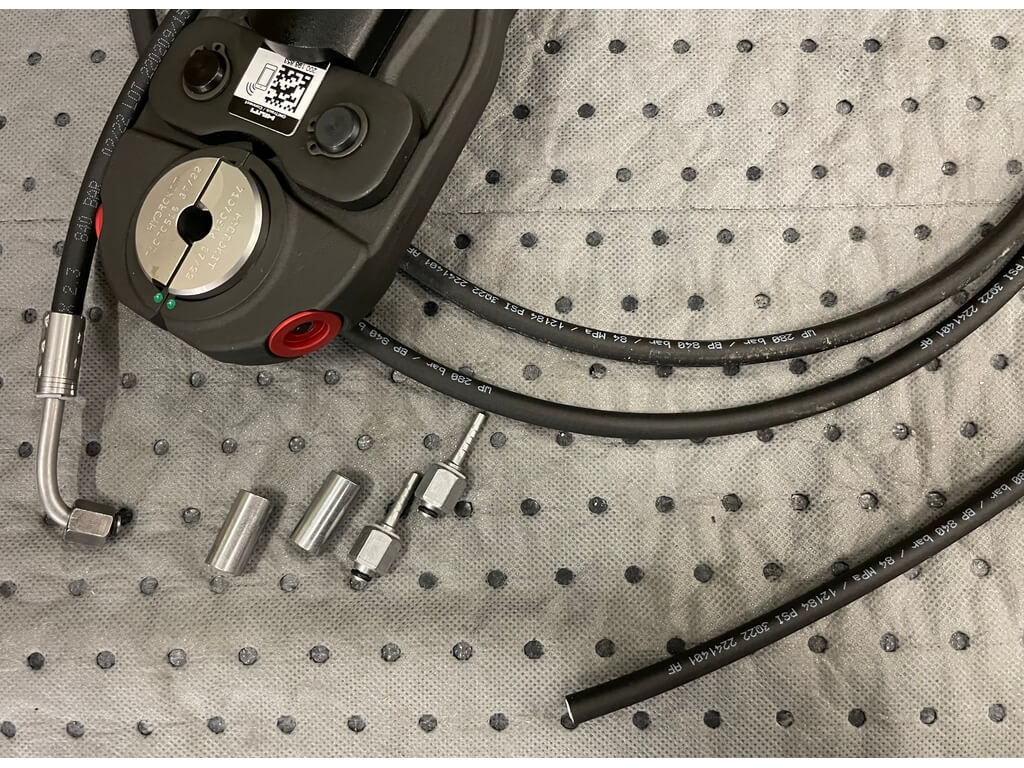

The ferrules are pre-crimped and equipped with an O-ring on the fitting side for a perfect seal. Portable system allowing one-handed crimping in small spaces.

4 - SIMPLICITY

Put the tip on, pull the trigger and that's it.

* Musculoskeletal disorders

What happens during the crimping process?

The crimping process is very simple and fast.

Using a portable crimping machine, it takes place in 6 steps:

1 - Definition of the length of the pipe and the type of ferrule (straight, 45° or 90° bent)

2 - Inserting the skirt on the pipe

3 - Inserting the end cap

4 - Opening the crimping tool

5 - Positioning the assembly in the crimping jaws

6 - Crimping and opening the crimping tool

In addition, you can be sure that all your hoses will be crimped correctly and to the right dimension.

Crimping machine not supplied, Hilti reference: NPR 19-A + NPR PM jaw holder