Hydraulic testing station - CHESS

It is the ideal tool for testing equipment in the workshop.

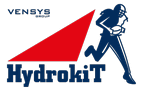

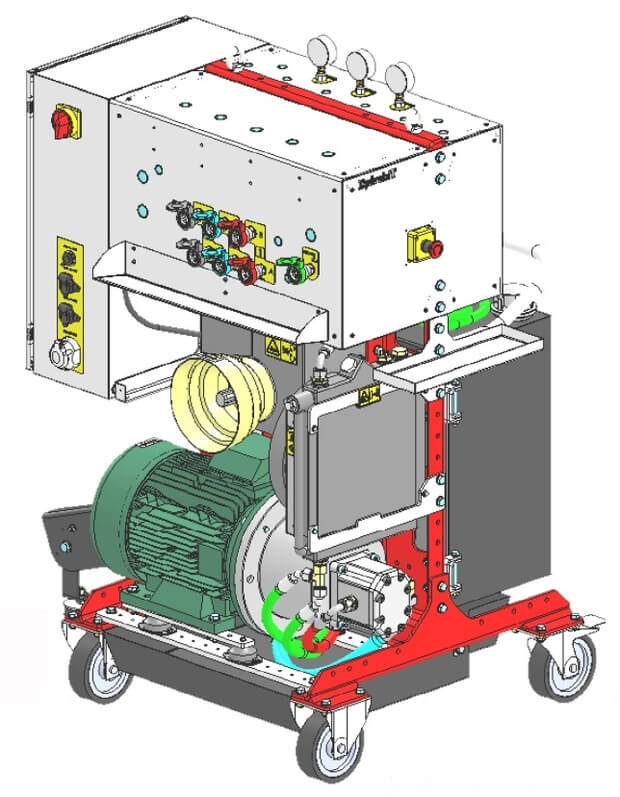

With the aim of improving the working comfort as well as the safety in the workshop, Hydrokit has developed the Hydraulic Test Station.

Defined on a case by case basis, according to the customer's specifications, it aims at replacing the use of a tractor dedicated to the tests in the workshops.

Electrically powered, it allows autonomous and safe work to perform both hydraulic and electrical tests.

Benefits

1 - Replaces the tractor for testing coupled equipment in the workshop

2 - Operating safety that a tractor does not provide (emergency stop, thermocontacts)

3 - Safety power take-off (optional) speed control from 0 to x rpm + retractable stabilizer

4 - Electrically operated (no exhaust gases in the workshop)

5 - Can be moved by hand

6 - Easy to read flow and pressure measurements

7 - Lower investment

8 - Less energy consumed

9 - Less maintenance

10 - time saving (allows autonomous work)

Features

Hydraulics :

- Oil flow rate: up to 45 L/min

- Oil pressure: up to 200 bar

- Hydraulic pump: gears Group 2-3 up to 33cm3/rev

- Flow control: 3-way with single-turn adjustment 0-50 L/min

- Dispensing: 45 L/min with manual controls up to 5 functions/LI>

- Couplings: Push-Pull ISO-A with flap plugs

- Pressure gauges: 0-250 bar on each function

- Tank: 80 or 100 Litres

- Filtration: 25µm semi-submerged return filter

- Maximum oil temperature: 80°C

Electric :

-

Motor type: 3-phase asynchronous

-

Motor power: 3-4-5.5-7.5-11-15 kW

-

Engine speed: 1500 rpm

-

Motor current: from 6.2 to 28.1 A (400V)

-

Complete electrical cabinet (ARU, Elec ON/OFF control, Lighting test controls)

-

Auxiliary power supplies 12VDC - 10A (1 x 7-pin trailer socket, 2 x 3-pin socket, 1 x 2-pin socket)

-

High temperature protection

-

Automatic phase correction

-

Faulty indicator lamps

-

Direct or soft start of the motor

Options :

-

Distribution type PVG16/32, CETOP3 electrically controlled

-

Variable displacement pump

-

Radio-controlled hydraulic functions

-

1"3/8 6-spline PTO + Tower counter

-

Oil cooler

-

Hydraulic tester (flow info, pressure, temperature)

-

Hour meter

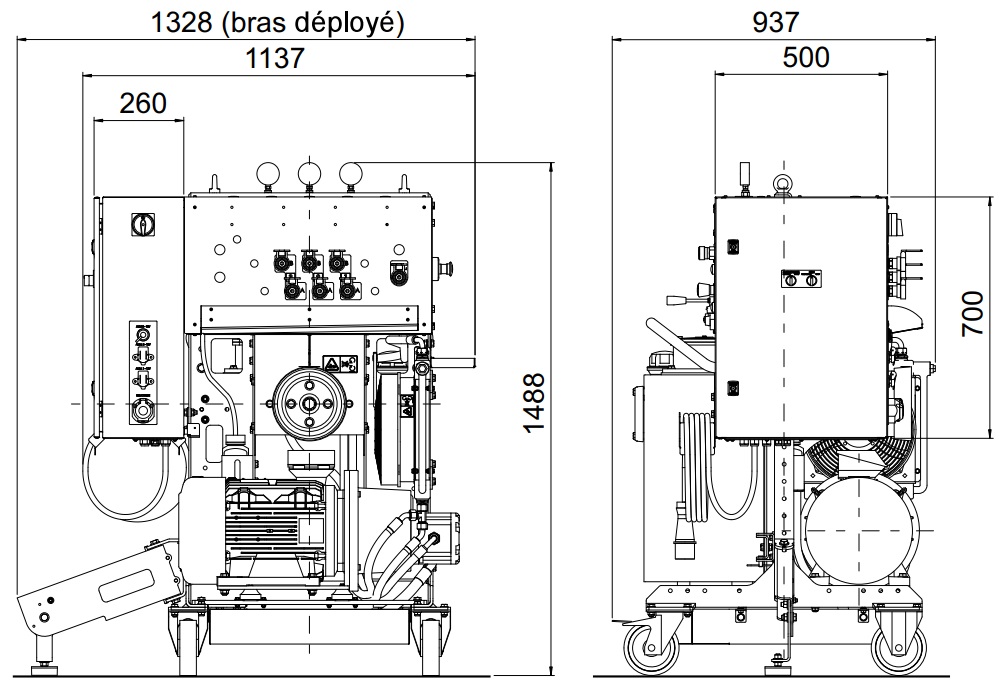

General dimensions

- Maximum width : 1328 mm

- Maximum length : 937 mm

- Height : 1488 mm

- Weight without oil: Depending on equipment up to 500 kg

- Weight with oil: +60 kg to +80 kg depending on the tank

- Oil tank volume: 80L or 100L

- Cabinet dimensions: 500x700x260 mm

Description